Quality & Inspection

MFG Electronics, Inc. works to ISO 9000 standards and performs thorough inspections at several key points in the assembly process.

We firmly believe that the lowest cost and highest quality are obtained by building it right the first time. Our reputation with customers for consistently meeting their most demanding quality and delivery objectives rests in large part on:

- Our thorough inspections procedures, multiple soaks, high pressure water washes, and rinses in deionized water.

- Our highly trained and dedicated employees.

Full Electrostatic Discharge (ESD) protection is implemented throughout the entire manufacturing floor.This includes the use of anti-static mats, anti-static workstations, wrist straps, a statguard ESD protective floor finish, mechanical racking with full ESD protection, conductive static-shielding bags, and an ESD strap tester.

About Our Inspection Process

We have standardized our internal inspection procedures on the following tasks:

- Receiving Inspection: All incoming material purchased for customers by MFG Electronics, Inc. is inspected before it is placed in inventory.

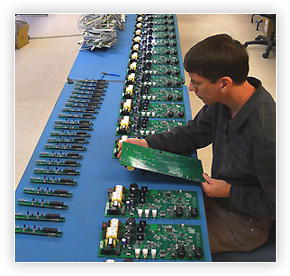

- Kit Audit and Parts Preparation: Whether pulled from internal inventory or received as a consignment kit, all components are reviewed vs. the BOM for correct quantities and correct parts. Shortage reports are generated and managed. Leaded parts are formed so that label information will be face up and can be inspected after installation on the PCB.

- Post Surface Mount/Pre Wave Inspection: 100% of all parts are inspected for proper location and orientation. This includes all through hole and surface mount devices. Open locations are checked against a shortage report and the assembly drawing.

- Post Wave and Post Reflow Inspection: 100% of all parts are inspected for proper wetting, shorts, bridging, and parts are straightened where necessary.

- Final Inspection: 100% of all assemblies are inspected against the assembly drawing, a list of generic items, and a key list of special items developed for each particular assembly.

- Outgoing Inspection: Every shipment is inspected by the quality manager to ensure all the paperwork and other inspections have been done according to internal procedures.

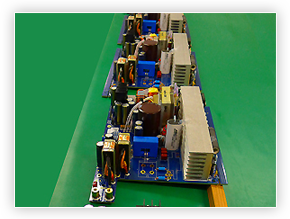

Lead free power supply assemblies

Final inspection before packaging for shipment